Jan van der Kaaij, Managing Partner and Co-Founder and Nikkie Vinke, Senior Consultant at Between-us | July 9, 2015

Innovating and partnering to resolve societal issues can unlock massive value.

Fashion is one of the most polluting industries, second only to oil. The overall textile industry is responsible for 10 percent of global CO2 emissions, and 25 percent of the world’s pesticides are used for growing cotton. The production of one kilogramme of cotton – the required amount for a pair of jeans – involves an average of 8,000 litres of water, the equivalent capacity of a small truck.

The dyeing of 1 kg of textiles requires another 70-150 litres of water. On a global scale, in two years the entire fashion industry uses the same amount of water as there is in the Mediterranean Sea. Meanwhile more than a billion people across the globe lack sufficient access to water, and by 2025, two-thirds of the world’s population is expected to face infrequent water shortages.

Employing approximately 75 million people and producing around 80 billion new garments a year, the global apparel market is associated with an extensive range of social and environmental issues. With the emergence of fast fashion and the prediction that the global apparel business is to generate double digit growth between 2014 and 2020, substantial societal pressures are mounting on the way clothing retailers manufacture their garments.

The fast fashion business model is based upon short cycles of the latest trends. It was successfully pioneered by Spanish brand Zara and focuses on quick development and turnover at bargain prices. At the same time, supply chains have increasingly become complex as almost the entire production of apparel has  been relocated to Asia, Africa and Eastern Europe, making them difficult to oversee.

been relocated to Asia, Africa and Eastern Europe, making them difficult to oversee.

For Zara’s mother company Inditex manageability is one of the main arguments to opt for ownership of factories, as Inditex prides itself in delivering quality mercha

ndise in as little as three weeks from its own factories. But since their success is followed by ever more fashion brands, there is a growing amount of orders that need to be processed faster and at cheaper rates. With that development, the risk increases that corners are being cut by local suppliers, for instance on working hours, wages and safety.

Disruptive innovation for society

Clearly, fashion needs to deal with this myriad of issues. Next to improving the industry standards through valuable vehicles such as the Sustainable Apparel Coalition[1], innovation is the next step for the industry.

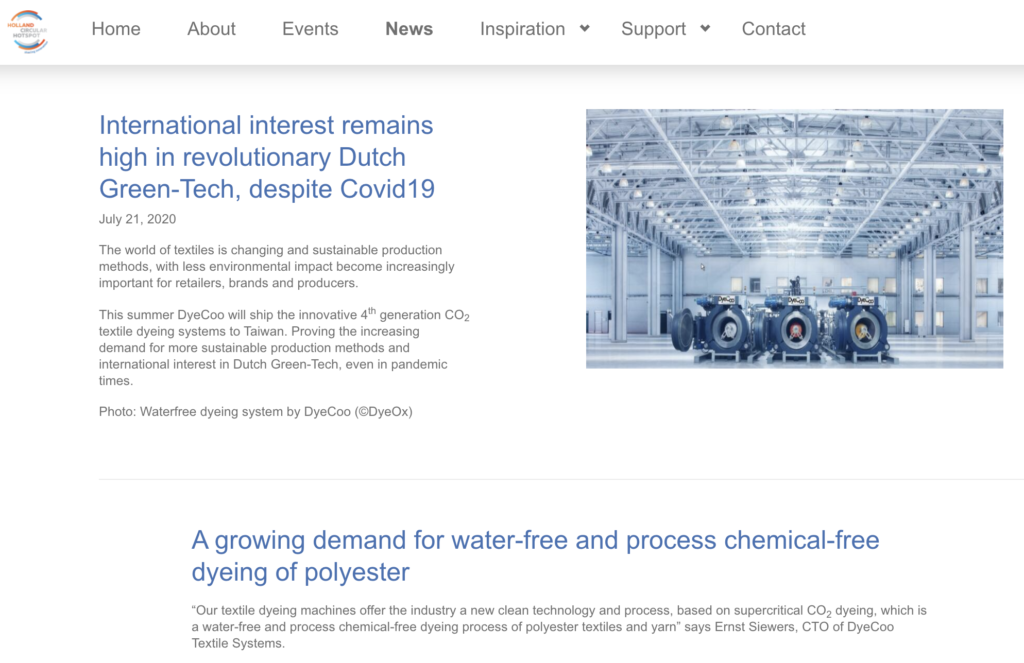

“For Nike, sustainability is a powerful opportunity to innovate”, says Hannah Jones, Nike’s chief sustainability officer and VP of the company’s Innovation Accelerator, in a recent interview. Nike identified water inadequacy and resource cost volatility among the risks, opportunities and challenges surrounding its business. This became the driving force behind the forging of the relationship between Nike and Dutch award-winning startup DyeCoo, a Dutch company that launched the world’s first ever industrial dyeing machine that uses high pressure carbon dioxide (CO2) as a replacement for water to dye polyester. The CO2 used in the process originates from other industrial sources and is 95 percent recyclable. On top of that, the technology uses less chemicals and about half the energy of conventional dyeing techniques.

With an estimated 39 million tonnes of polyester dyed annually, the massive market opportunity for DyeCoo was reason enough for Nike to become a shareholder in the company. Late 2013, Nike celebrated the opening of its first water-free dyeing facility at one of its suppliers featuring DyeCoo’s machines. The garments dyed with the technology were branded as “ColorDry” to highlight the environmental benefits and unprecedented colouring achieved with the technology. Nike released its first DyeCoo-dyed product, the ColorDry Polo, in June 2014.

Nike was not the only one to spot the opportunity; it also attracted other suitors such as IKEA that became a co-investor in DyeCoo, and Adidas, which used DyeCoo-technology to launch its proprietary DryDye concept.

To enable the technology, DyeCoo also signed a collaborative agreement with Huntsman Textile Effects, a leading pigment-producing enterprise headquartered in Singapore. Their partnership was aimed at the development and growth of finishing products and fluorescent brighteners, to be produced by Huntsman and used in DyeCoo’s machines.

Scaling a sustainable innovation

The complex supply chain that DyeCoo is operating in results in many constraints for its business model (refer to figure 1). Scaling up is a basic prerequisite for DyeCoo in order to create the societal and financial impact that the company’s shareholders aspired to. Because of the huge investments and reliability requirements, selling DyeCoo’s dyeing machines remains a difficult and sometimes elusive process. While its technology has often been described as revolutionary, DyeCoo discovered that radical change within the clothing industry needs time, a lot of time.

Since the remaining obstacle for growth today is the wait-and-see approach within the textile market, DyeCoo is working hard to develop the next version of their technology, as well as other applications such as rendering textiles water resistant and fireproof. Furthermore, the company is focused on finding a solution for dyeing cotton with CO2 and on forging new alliances. To date, DyeCoo has a worldwide capacity of 32000 litres and growing. With this volume, DyeCoo remains a miniscule player in a huge global market. Meanwhile, customers keep coming and the future looks bright. Next to Nike and Adidas, Swedish outdoor apparel brand Peak Performance has also launched products that are using DyeCoo technology.

From stakeholder engagement to value chain collaboration

In line with the successes of blockbuster products such as the enzyme-based low temperature washing detergents of Novozymes for P&G and others, the example of Nike and DyeCoo illustrates that there are smart ways to unlock the market potential of sustainability issues. But turning such issues into opportunities is not easy; it requires a partnering approach, not just an isolated technological innovation. A prerequisite for success is therefore to first interact with stakeholders to deeply understand their sustainability concerns. From this understanding, the impact and market potential can be revealed. With enough potential , the stakeholder engagement will also come in useful in the development of the required partnering platform. In short, value chain collaboration should be regarded as a key differentiator to turn sustainability issues into tangible business opportunities.

Nikkie Vinke is Senior Consultant at Between-us, a strategy and sustainability consultancy.

Jan Van Der Kaaij is the Managing Partner of Between-us and a partner in INSEAD’s Leading the Business of Sustainability executive development programme. He is also a member of the INSEAD Sustainability Roundtable Advisory Board.

[1] The Sustainable Apparel Coalition is a trade organization comprised of brands, retailers, manufacturers, government, and non-governmental organizations and academic experts, representing more than a third of the global apparel and footwear market. The Coalition is working to reduce the environmental and social impacts of apparel and footwear products around the world.

Read more here